Innovation in development

“As a master’s thesis student, your project and dedication have the power to make a meaningful impact and contribute to the company’s success.”

Having studied automation technology, Daniel found himself drawn to a career in electronics within the chemical sector, eventually landing at Dow.

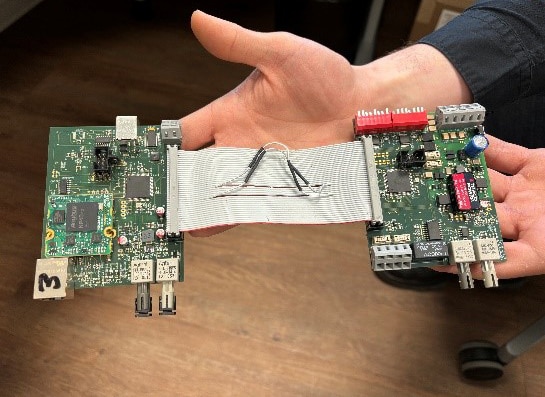

Formerly a dual student and now a Dow Stade employee, Daniel not only conceptualized but brought to life a groundbreaking module. This invention facilitates seamless integration between the aging Process control system 'MOD5' and other systems, gaining widespread recognition within Dow. The module has found application in multiple Dow facilities. Daniel's educational journey led him to specialize in automation technology at the Hamburg University of Applied Sciences (HAW), simultaneously completing an apprenticeship as an electronics technician for industrial engineering.

Where did the project start?

"The journey began in 2020, during my master's thesis at the Hamburg University of Applied Sciences (HAW). Collaborating with Dow's TES Support & Sustainment department, we were looking for a compelling topic for my thesis. Swiftly, we identified the challenge: creating an interface to facilitate communication between the outdated MOD5 control system and other plant systems, moving towards a standardized protocol."

Can you tell more about the MOD5 system?

"The MOD system is an in-house development by Dow from the 1960s (MOD1), MOD5 was created in the 1980s. It uses a special internal protocol that is only spoken by this system. This makes it very difficult to communicate with other standard IT systems on the market. My goal was to develop an interface that connects the MOD5 system with standardized protocols to enable communication with other systems."

How did you approach this challenge?

"First, I analyzed the language of the MOD5 system and tried to reprogram it on a microcontroller. The next step was to implement a standardized protocol on another microcontroller. In the final phase, these two components were intricately linked in the software. After completing the software development phase, I transitioned into prototyping the boards. This involved tasks such as hardware design layouting, selecting components, soldering the electronics, as well as testing and debugging. Having established a connection between the systems, we meticulously identified and addressed potential limitations. At the end, the module ended up working like an interpreter between the two systems that speak different "languages" - as if one speaks "Spanish", the other "Japanese", and the module translates."

When did you realize that you were making significant progress?

"A pivotal moment in the development occurred when the first parts of the MOD5 system in the RVA were slated for migration. My mentors, engaged in the project, recognized the potential of my work early on. Despite not yet reaching the "board status," we collaborated on further planning, verified components, and defined device requirements, including immunity to interference. Within weeks, the project team decided to move forward with the new module as the migration solution for the RVA.

Meanwhile, we engaged with an electronics manufacturer in Hamburg (Germany) to prepare the module for mass production—a challenging yet successful endeavor. Just before series production started, I completed and successfully defended my master's thesis. At the same time, we passed the TÜV test successfully."